Monday - Saturday 8AM -7PM

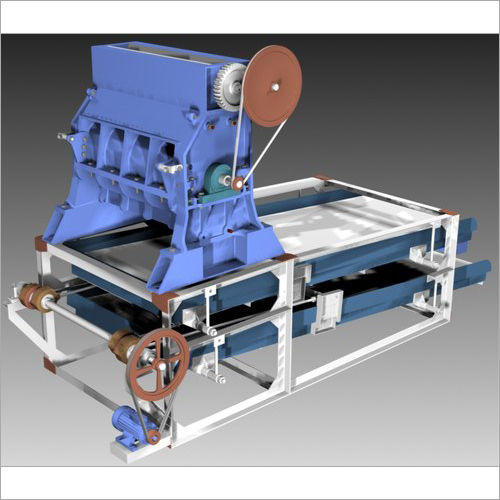

Cotton Seed De-Hulling Plant

1000000 INR/Set

Product Details:

- Type Cotton Seed De-Hulling Plant

- Material Mild Steel

- Capacity 1000-1500 Kg/Hr

- Computerized No

- Automatic Grade Automatic

- Control System PLC Control

- Air Compressor Power 15 HP

- Click to View more

X

Cotton Seed De-Hulling Plant Price And Quantity

- 1 Ton

- 1000000.00 - 5000000.00 INR/Set

- 1000000 INR/Set

Cotton Seed De-Hulling Plant Product Specifications

- Cotton Seed De-Hulling Plant

- 3500 Kg

- 22 kW

- 380 V

- 4500 x 2500 x 3200 mm

- 500 Liters

- Mild Steel

- PLC Control

- Automatic

- 1000-1500 Kg/Hr

- No

- Large

- 2500 mm

- 15 HP

Cotton Seed De-Hulling Plant Trade Information

- 10 Ton Per Month

- 1 Months

Product Description

Cotton Seed De-Hulling Plant is a highly durable and sturdy industrial system which is commonly used in the agricultural industries for the removal of hulls from beans and other seeds. It is designed and developed as per industrial standards for higher efficiency and durability of the system. This standalone fully automated system is equipped with high performance drives with a power rating of 100 horse power to achieve a production capacity of 50 ton per day.

Product Details

Brand | Mitsun |

Capacity | 50 tons per day |

Power | 100 hp |

I Deal In | New Only |

Automation Grade | Automatic |

Rust Resistance | Yes |

Material | Cast Iron,MS Sheets |

Superior De-Hulling Performance

This plant consistently achieves up to 98% shelling efficiency, ensuring maximum yield from cotton seeds with minimal wastage. Its automatic feeding system and PLC control optimize every batch, providing reliable and uniform results regardless of operational scale.

Engineered for Industrial Demands

Constructed from robust mild steel and finished with a powder-coated layer, the plant is built for longevity. Its large air tank (500 liters) and 15 HP compressor support sustained high-capacity operations, making it suitable for sizable agricultural enterprises, traders, and exporters.

User-Friendly Automation and Safety

With automatic features and a modern PLC control system, operation is streamlined, reducing manual labor. Integrated safety measures, including emergency stop and overload protection, promote a secure working environment. The low maintenance design further minimizes downtime and operational costs.

FAQ's of Cotton Seed De-Hulling Plant:

Q: How does the Cotton Seed De-Hulling Plant operate?

A: The plant uses an automatic vibratory feeder to supply cotton seeds, which are then processed through a de-hulling mechanism managed by a PLC-controlled system. The process separates the hull from the seeds efficiently, achieving a shelling rate of up to 98%.Q: What are the benefits of using this de-hulling plant over traditional methods?

A: This plant offers higher efficiency, reduced labor requirements, and consistent output quality. The automated feeding and PLC control system help lower operational errors, while low noise levels and built-in safety features provide a safer working environment.Q: When and where is this plant best installed?

A: The plant is suitable for installation in commercial agricultural processing facilities, especially where high capacity and reliability are required. Onsite installation is available, ensuring proper setup and integration into your production line.Q: What types of cotton seed can the plant handle?

A: The plant is designed for seeds with a moisture content of 8-12%, allowing it to adapt to regional harvest conditions across India and other similar climates.Q: How is maintenance handled for this de-hulling plant?

A: The equipment is engineered for low maintenance, with durable components and a robust design. Routine checks and standard machine cleaning are generally sufficient to keep the plant running efficiently.Q: What safety measures are integrated into the plant's operation?

A: Key safety features include an emergency stop mechanism and overload protection, which guard both the operators and machinery against accidents or equipment damage during operation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email