Monday - Saturday 8AM -7PM

Showroom

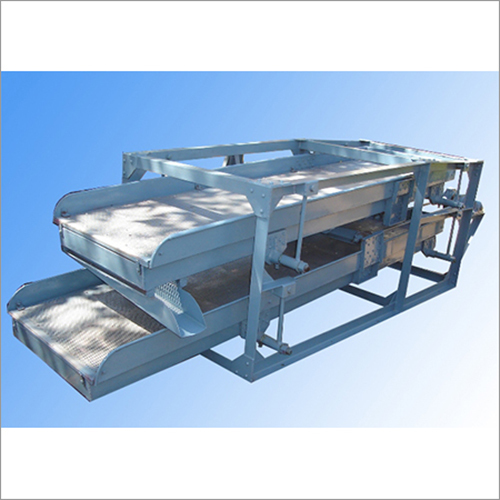

Oil Mill Machines are manufactured and supplied by our workers by making use of premium grade of raw materials and modern technology. This machinery is mainly designed to be used for extracting the oil properly.

Oil Processing Equipments offered by us, are specially designed to be used for various oil extraction. Our expert manpower uses best quality cast iron and mild steel, sourced from trusted vendors to manufacture this machine.

Industrial Oil Refinery Plant are designed to transform and refine the oils into more useful products for further usage. This refinery changes the crude oil into petroleum products for use as fuels for transportation, heating, paving roads, and generating electricity and as feedstocks for making chemicals.

Edible Oil Refinery is well acknowledged for its smooth & noiseless operation and less power consumption. This plant has easy installation, simple operation, and high performance too. This is very effective as well as economical both.

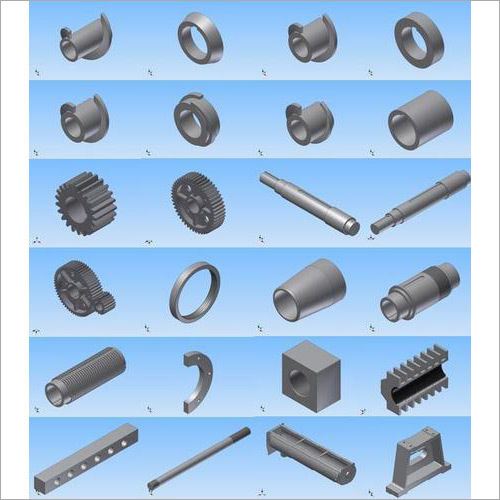

Single Chamber Expeller is widely designed for greater flexibility, capacity and efficiency. This chamber expeller is ideal to be used in food processing industry. This expeller is tested on various parameters to ensure long functional life and high output rate.

Double Chamber Expeller is provided with a heavy duty double reduction gear box construction. These are the models of superlative workmanship that also boast of the capacity to yield radial axial loads for the task of seed crushing.

Cotton Seed Oil Mill is designed to provide emphasis on energy efficiency, cost reduction by reducing hexane loss and other important utilities, improved quality of products and so on. This mill is very effective as well as economical too.

Edible Oil Extraction Machinery is mainly used for the proper extraction of oil from seeds and so on. The provided machinery is well acknowledged for its smooth & noiseless operation and less power consumption.

Oil Expeller can run on diesel engines which are highly suitable for areas where there is shortage of electricity. This is designed and developed using advanced technology, hence is energy efficient in their functioning.

Oil Extraction Machinery is basically manufactured and supplied by our workers by making use of optimum grade of raw materials and upgraded technology. This machinery is very much appreciated by our customers in the market.

Batch Type Refinery is widely used to refine the different types of oils. This refinery is preferred because it is low cost and quite easy to operate. This refinery uses multiple of process for refining the edible or other oils.

A facility specifically created for the processing of cotton seeds to remove their outer hulls is the cotton seed hulling plant. In order to produce cottonseed oil and other cottonseed byproducts, it is an essential step. The facility uses sophisticated equipment and technology to successfully remove the hulls from the seeds.

Innovative and effective machinery called peanut oil extraction machines are used to extract high-quality oil from peanuts. These devices provide a practical and dependable solution for both industrial and domestic use by streamlining the procedure of extracting oil from peanuts.

For both residential and commercial usage, our selection of mustard oil expellers provides a dependable and effective solution. Our devices are designed to give great performance, guaranteeing that you can extract the most oil whether you are a home cook or a professional chef.

Call Me Free

Call Me Free